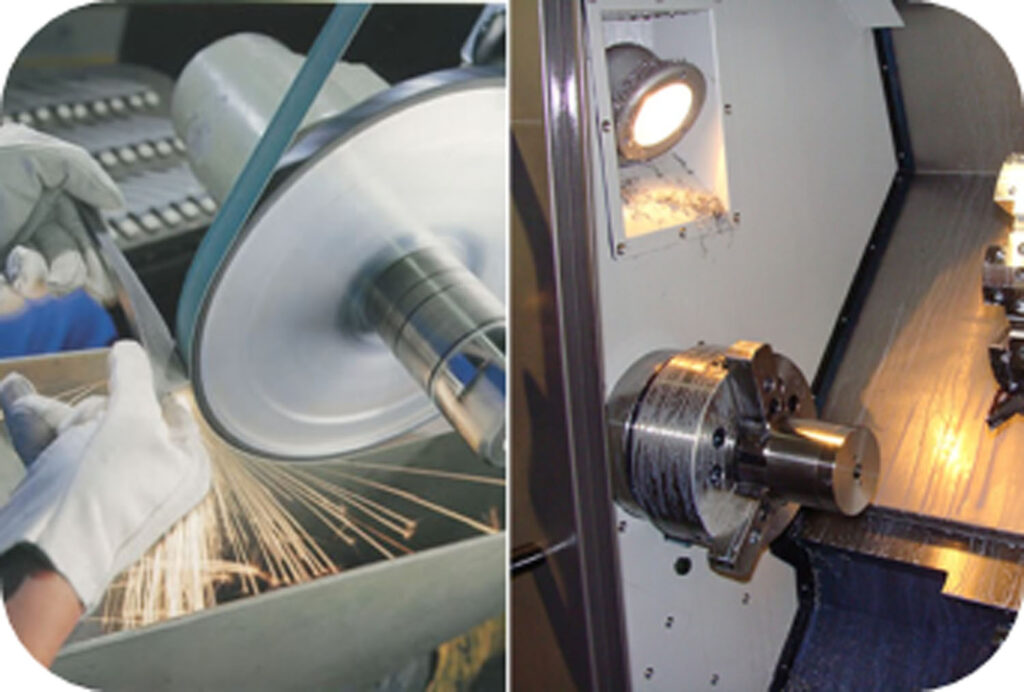

High-quality raw materials and accessory equipment for the lost wax investment casting, meeting each customer’s specific requirements.

In order to produce high-precision and complex castings, you need to work with top-quality consumables – raw materials and auxiliary equipment.

As long-time key suppliers of raw materials and accessory equipment, we are committed to pursuing excellence in our activities. We are ISO 9001:2015 certified. As we always strive for customer satisfaction, we focus on high-quality standards for our products and continuous improvement of the way we serve our partners.

Review our wide range of raw materials and accessory equipment:

Interested in learning more about our services?

Please do not hesitate to contact us. We will get back to you without delay.

IMC Valuable Partners