We offer highly sophisticated wax and ceramic injection machines that feature real-time monitoring and control of all injection parameters. Our wax melting and conditioning technology maintains a constant wax viscosity which produces consistent wax patterns.

A large variety of optional features can be added to the basic machine configuration to meet your specific needs and demands for productivity, control, quality, and patterns traceability.

Interested in learning more about our services?

Contact us today and one of our expert team members will be happy to provide you with all the information you need. Don’t miss out on this opportunity and contact us!

Wax Injectors

Wax Injector, 4 Post

MPI 35 series, 100, 200

and 300 US tons clamp force

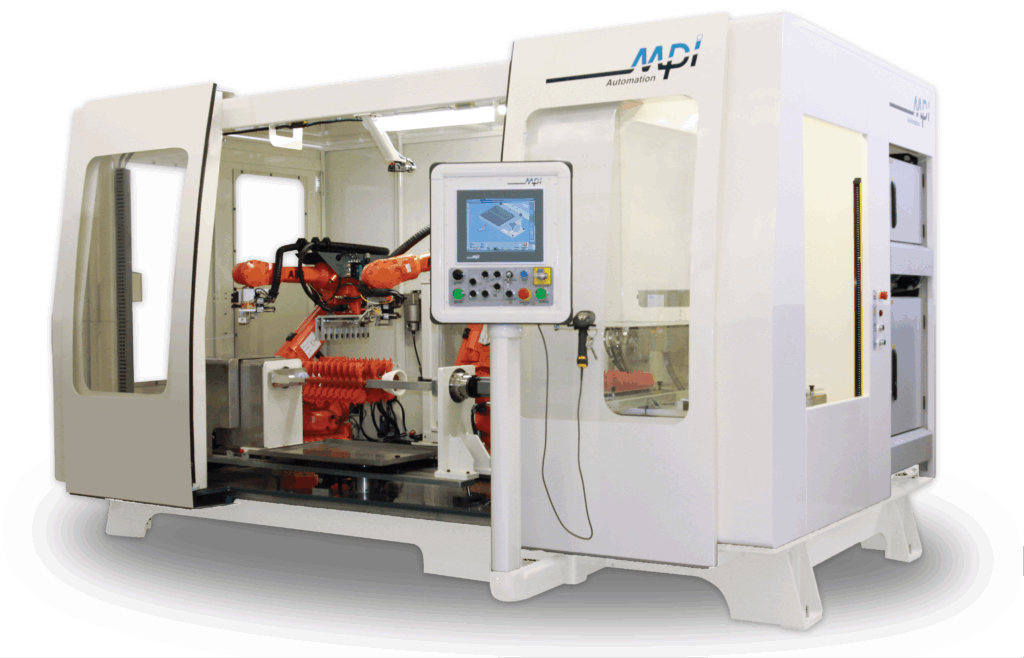

Automatic, Horizontal C-Frame

MPI 45 series, 12

and 25 US tons clamp force

Semi-automatic, C-Frame

MPI 55 series, 25, 50

and 100 US tons clamp force

Industrial Gas Turbine, C-Frame

MPI 55 IGT, 50

and 100 US tons clamp force

Semi-Automatic, Two-Station

MPI 105-12,

Two 12 US tons clamping units

Ceramic injector

Semi-Automatic, C-Frame

MPI 56 series, 25, 38, 50

or 100 US tons clamp force

Process control

Process Vision

Graphing Unit

MPI 20-20

Wax melter

Direct Melter

MPI 97 series, 50

or 200 lb/hr melt capacity

Wax preparation and transfer unit

MPI 95-25 series,

50 or 200 lb/hr melt capacity.

Do not hesitate to contact us for further information.