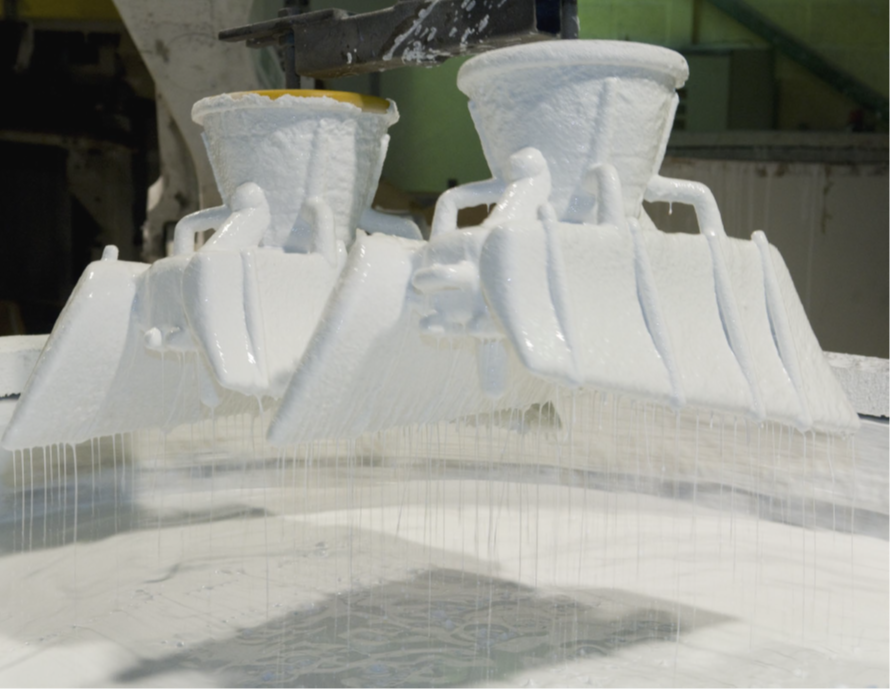

IMC distributes the Nalco® “Water’s Engineered Shell Systems” products in Europe: innovative complete shelling solutions purposefully designed to meet the specific needs of investment casting foundries.

This comprehensive system will contribute to your process performance optimization, such as higher throughput and scrap reduction, while being able to accommodate your foundry’s specific needs, such as casting detail coverage, ease of shell removal, or high hot strength.

We also offer onsite technical support to help maximize your profitability.

Nalco® water investment casting product line includes:

- Colloidal Silica binders.

- Other process additives including wetting agents, antifoams, and biocides.

Advantages of using the water’s engineered shell systems:

- faster dry times,

- fewer dips,

- less shell cracking,

- improved casting surface finish,

- optimized total cost of operation.

You will find some examples of Colloidal Silica Binders offered by Nalco®.

| Typical Value | 1030 | 1130c | 6009c | ESB6 | ESB Prime | Rainier | ETNA |

|---|---|---|---|---|---|---|---|

| Concentration SiO2 | 30% | 30% | 30% | 27.6% | 28.5% | 26% | 30% |

| Average Particle Size (nm) | 13 | 8 | 12 | 13 | 13 | 13 | 8 |

| Specific Gravity @ 77°F/25°C | 1.206 | 1.215 | 1.209 | - | 1.197 | - | - |

| pH (@ 77°F/25°C) | 10 | 10 | 10 | 10 | 10 | 10 | 10 |