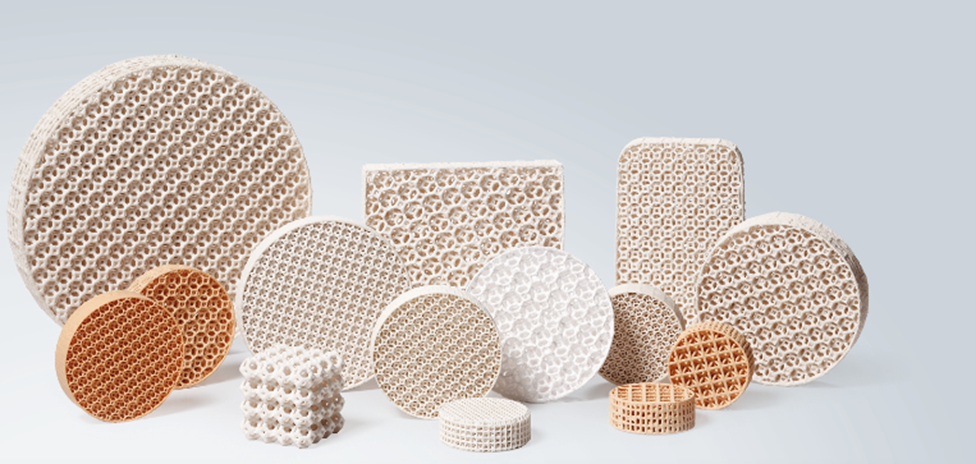

Different sectors of the precision investment casting industry place different requirements on the refractories used for crucibles. Various types of crucible material are available to meet the preferences in terms of reaction, erosion, and thermal shock.

Our portfolio of accessory products for the investment casting foundries also includes a full range of Aluminosilicate, Alumina, Graphite based, Magnesia, Silica/Quartz, and Zirconia crucibles, with capacities of 0.7kg up to 3000 kg. The crucibles up to 220mm in diameter are manufactured by isostatic pressing and are pre-fired to high temperatures. The biggest sizes with a capacity of up to 3000 kg are cast.

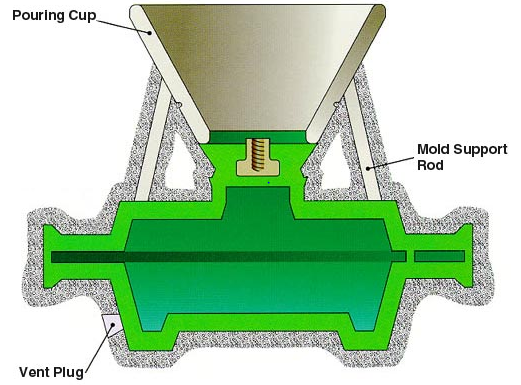

IMC can also provide the appropriate backing materials to increase crucible life if necessary. The outer casing of the backing material is either the coil screed or else a backup crucible, usually known as a SLEEVE. As the sleeves are in a non-critical position and do not experience the heat or chemical interaction that the crucible experiences, they can be made from a less refractory and cheaper material; the main qualities should be high strength and good thermal flexibility.

The field of applications in various industries: aerospace and aircraft industries, automotive industry, energy industry, medical industry, and commercial industry

Please find below a chart showing some physical properties, and chemistry of Zirconia, Zircon, alumina, Aluminosilicate, and graphite-based crucibles:

| Zirconia | C | C2 | M |

|---|---|---|---|

| Physical Properties | |||

| Bulk Density (g/ml) | 4.37 | 4.58 | 4.46 |

| Apparent porosity (%) | 21.0 | 19.0 | 20.6 |

| Chemistry | |||

| SiO2(%) | 1.3 | 0.8 | 0.6 |

| Fe2O3(%) | 0.1 | 0.1 | 0.1 |

| CaO(%) | 4.1 | 3.6 | 0.2 |

| MgO(%) | 0.2 | 0.3 | 2.8 |

| ZrO2(%) | 93.0 | 94.4 | 95.6 |

| Alumina | A97 | 90 | AZ80 |

| Physical Properties | |||

| Bulk Density (g/ml) | 2.95 | 2.80 | 2.96 |

| Apparent porosity (%) | 22.4 | 20.4 | 21.6 |

| Chemistry | |||

| SiO2(%) | 1.4 | 10.5 | 8.4 |

| Fe2O3(%) | 0.2 | 0.1 | 0.1 |

| ZrO2(%) | - | - | 14.7 |

| Al2O3(%) | 97.9 | 88.5 | 76.2 |

| Aluminosilicate | Silimanite AM1 | Mullite F80 | Silica FS60 |

| Physical Properties | |||

| Bulk Density (g/ml) | 2.35 | 2.58 | 1.90 |

| Apparent porosity (%) | 22.0 | 19.0 | 25.0 |

| Chemistry | |||

| SiO2(%) | 33.5 | 20.5 | 59.5 |

| Fe2O3(%) | 0.6 | 0.05 | 0.25 |

| Al2O3(%) | 64.5 | 79.0 | 39.5 |

| Alkalies(%) | 0.2 | 0.2 | 0.6 |

| Graphite Based | Clay-Graphite | Silicon Carbide | |

| Physical Property | |||

| Apparent porosity (%) | 27-32 | 25-29 | |

| Chemistry | |||

| SiO2(%) | 25-30 | 5-15 | |

| Al2O3(%) | 10-15 | 5-15 | |

| SiC(%) | 10-25 | 25-40 | |

| Si(%) | 5-10 | - | |

| C(%) | 30-45 | 40-50 | |